Product Description

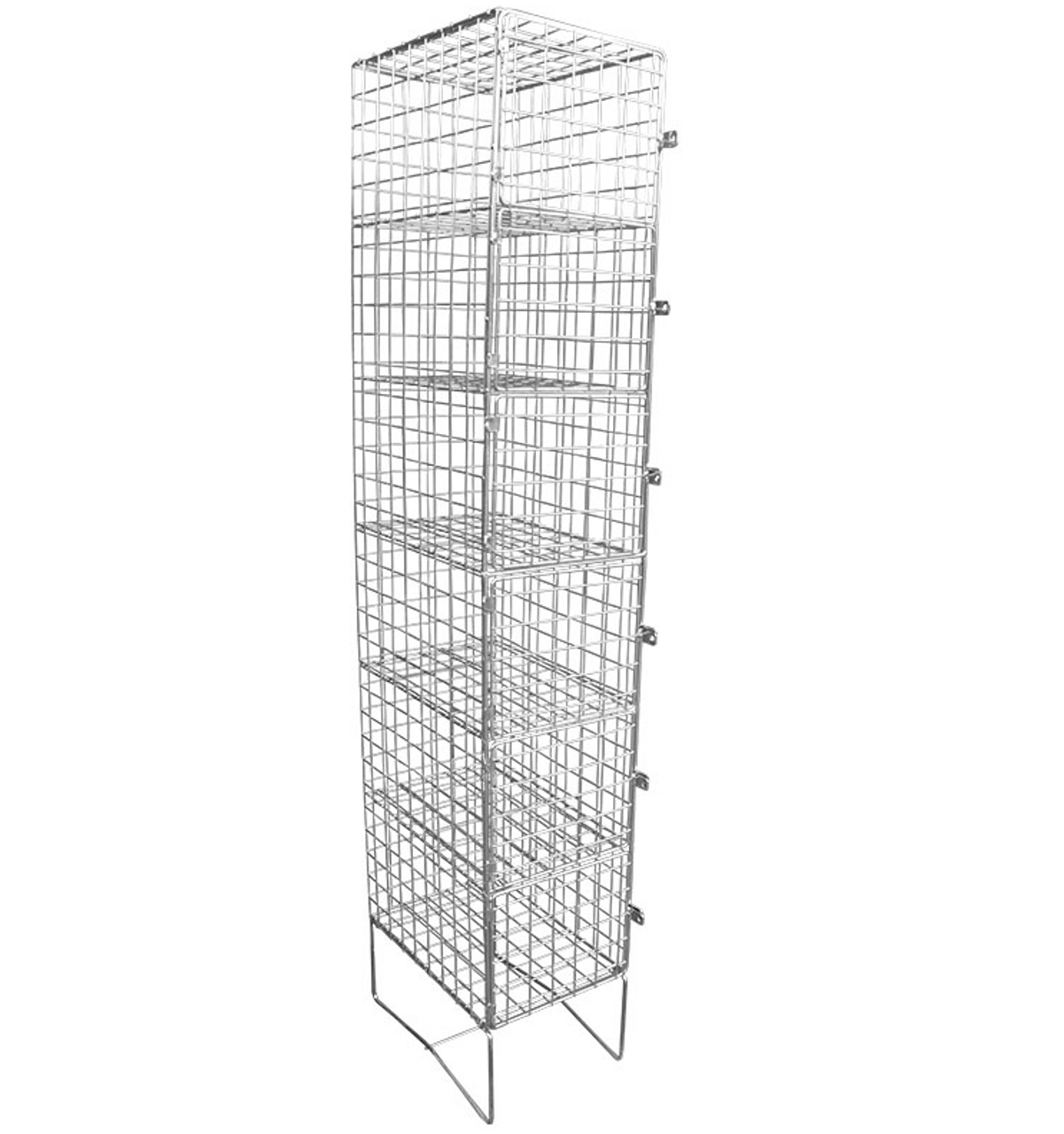

Our Wire Lockers are durable storage solutions perfect for offices, schools, gyms, and more. With various compartment options including 1 door, 2 door, 3 door, 4 door, 5 door, and 6 door configurations, you can customize the locker to fit your needs. Each locker is electroplated for a sleek finish and measures 1800mm H x 300mm W x 450mm D. The Wire Lockers are secure, versatile, and built to last, making them the ideal choice for organized and efficient storage solutions. Upgrade to Wire Lockers today for a clutter-free and organized space.

Wire lockers are storage units made from durable wire mesh that serve as secure spaces to store personal belongings in schools, offices, gyms, and other facilities. These lockers are designed to provide ventilation, visibility, and security, making them an ideal choice for storing items in public spaces. Wire lockers come in various sizes and configurations to accommodate different storage needs, and they are often used in shared environments where individuals need a secure place to store their belongings. Overall, wire lockers offer a practical and efficient solution for storing items safely and securely in a variety of settings.

Wire Lockers that work hard across South Africa

Some storage solutions look good on a brochure, then fall apart the moment they meet real life. You know the scene: wet overalls, muddy boots, PPE that needs to dry, staff moving fast, and a supervisor who wants fewer headaches, not more.

That's where Wire Lockers in South Africa earn their keep.

When buyers ask for Wire Lockers, they're usually chasing three things at once: airflow, visibility, and control. Not "control" in the heavy-handed sense. Control like: you can actually see what's happening, kit dries quicker, and missing items get noticed sooner. It's simple. It's practical. And it suits a lot of South African sites where dust, humidity, and shift change chaos are part of the daily playlist.

If you're specifying industrial Wire Lockers for a plant, hospital, mine, hotel group, or a commercial property portfolio, the big win is this: they reduce the small problems that quietly cost money. Damp uniforms. Smelly lockers. Lost consumables. Slow audits. Complaints about hygiene. Those issues don't look massive on a spreadsheet until they do.