Why Industrial Shelving Builds the Backbone of Warehouses

Every efficient warehouse starts at the shelf. Strong shelving doesn’t just hold product; it holds uptime, safety and workflow together. For South African operations facing space constraints, high throughput, and coastal corrosion risks, partnering with a trusted industrial shelving manufacturer makes all the difference.

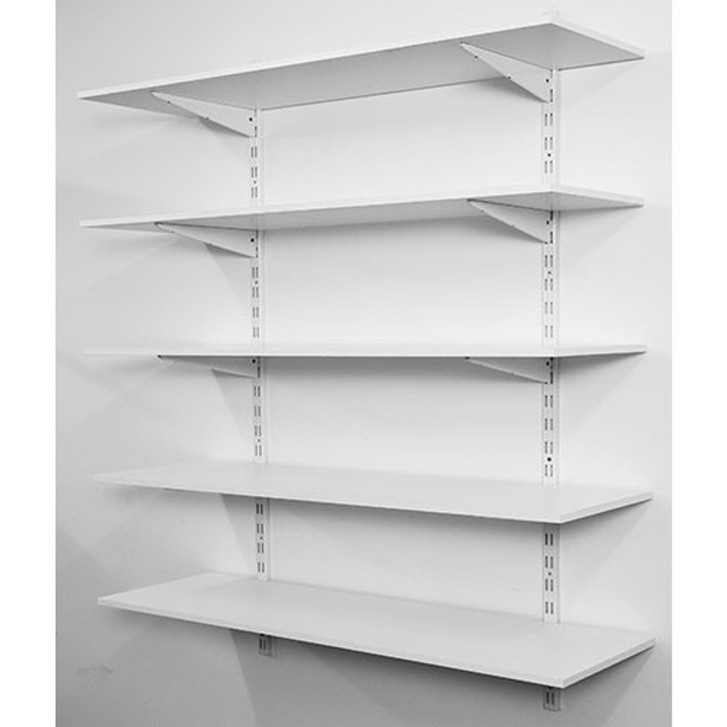

Dreymar Industrial designs shelving systems based on your site’s real data, from SKUs and handling equipment to floor conditions. We then integrate those solutions with racking, mezzanines, and materials handling equipment. The result? Steel shelving for heavy-duty loads, stainless or PVC options for hygiene-sensitive areas, gondola units for retail spaces, and mobile systems for high-density storage.

Key Takeaways

- Strength comes from engineered steel, stainless, and PVC shelving built to carry heavy loads.

- Efficiency is delivered through integrated racking + shelving layouts, mobile units, and mezzanines that cut travel time.

- Safety is ensured with anchored bays, verified loads, bracing, and routine inspections aligned to EN/SANS standards.

- QA matters: traceable materials, torque checks, weld testing, and coating validation protect long-term performance.

- Modularity supports growth with adjustable shelves, reconfigurable frames, and expansion-ready mezzanines.

- Costs stay clear when suppliers provide itemised pricing, lifecycle services, and transparent warranty coverage.

How Manufacturers Build Durable Shelving

- Material selection: steel for strength, stainless for hygiene, PVC for easy-clean environments.

- Frames & joints: engineered uprights, bracing, and reinforced fasteners.

- Surface finishes: powder coat or galvanizing to resist corrosion in SA climates.

- Load testing: shelf deflection, anchor pull tests, and torque verification.

Each step is documented, so when a supplier hands you load signage, you know it’s backed by engineering, not guesswork.

Engineering Choices that Drive Real Gains

Shelving works best when it integrates with racking:

- Mapping SKUs so fast movers sit at ergonomic heights.

- Pairing systems — pallet racking for bulk, shelving for cartons, cantilever for long goods.

- Adding mobility through mobile shelving in archive zones.

- Stacking vertically with mezzanines when floorspace runs out.

The result? Shorter pick paths, faster replenishment, and safer handling.

What We Check On-Site

When Dreymar surveys a site, here’s our checklist:

- Upright gauge and shelf thickness for expected loads.

- Anchoring method vs slab condition.

- Coating coverage in high-moisture or corrosive zones

- Pick path simulations with live SKUs.

- Torque and bracing checks during install.

This hands-on approach means fewer stoppages and a safer environment.

Buying Notes for South African Businesses

When comparing shelving suppliers, always confirm:

- Load ratings (per shelf + per bay).

- Duty class (light, medium, heavy).

- Growth potential (room for extra levels or mezzanines).

- Lifecycle costs (engineering, install, inspections, spares).

- Local presence (fast lead times, after-sales support).

Don’t just compare “shelving prices”, compare the full system and service package.

Safety, Maintenance & Modularity

- Anchored bays prevent tip risk.

- Clear load signage keeps teams safe.

- Routine inspections (daily user checks + annual EN 15635 audits).

- Modular adjustments let you change shelf pitch or add bays without starting over.

- Lifecycle support from installation to audits keeps performance reliable.

Verdict at a Glance

- Strength: reinforced steel, tested loads, durable finishes.

- Efficiency: dense storage layouts + mobile systems.

- Integration: shelving + racking + handling gear as one plan.

- Safety: anchored, labelled, inspected.

- Service: Dreymar provides local audits, spares, and training.

In short: the right shelving manufacturer delivers capacity, compliance and cost control in one build.

Frequently Asked Questions

- What’s the difference between shelving and racking?

Shelving = small/medium SKUs picked by hand. Racking = pallets or long goods moved with forklifts. Most facilities need both. - Which shelving materials are best in South Africa?

Steel for strength, stainless for hygiene, PVC for washdown or food zones. Powder coat or galvanising is critical for coastal sites. - How do I confirm safe load ratings?

Request stamped calculations, visible load signage, and anchor pull-test records from your supplier. - When should I use mobile shelving?

For high-density zones with predictable access frequency, like archives or slow-moving SKUs. - How often should shelving be inspected?

Daily operator checks, weekly supervisor scans, and annual expert audits per EN 15635.