Maximising warehouse space remains a top priority for South African businesses facing rising operational costs and limited expansion options. Choosing the right mezzanine floor for your facility can unlock valuable vertical space and streamline storage, making a significant impact on efficiency and profitability.

At Dreymar Industrial, we understand that every facility has unique needs. Our tailored mezzanine solutions, from rack-supported and shelf-supported mezzanines to custom multi-tier structures, are designed to address specific challenges in industrial storage, access, and materials handling. By assessing your requirements closely, we help you optimise your existing space and simplify day-to-day operations without the need for costly relocations.

Key Takeaways:

- Mezzanine floors maximise unused vertical space, offering significant cost savings and improved space efficiency for South African facilities compared to traditional expansion or relocation.

- Multiple mezzanine types are available, including structural steel, rack-supported, and shelf-supported solutions, each meeting different load, storage, and operational needs.

- Careful assessment of your facility’s height, load capacities, future adaptability, and regulatory compliance ensures optimal mezzanine selection and safe, long-term operation.

- Customisation options such as multi-tier layouts, flooring finishes, and integration with handling equipment enhance workflow, safety, and facility flexibility.

- Regular maintenance, quality materials, and professional installation significantly extend mezzanine lifespan, ensuring a strong return on investment and safer workplace.

Understanding Mezzanine Floors and Their Benefits

Mezzanine floors use the unused vertical zone in a facility, creating extra square metres above the existing floor. These semi-permanent structures solve common warehouse issues by turning wasted headroom into valuable storage, office, or production space.

Industrial environments often experience pressure as storage needs grow. A well-designed mezzanine makes expansion possible within current building limits. We see most facilities save 30%–50% in new setup or relocation costs by choosing a mezzanine floor instead of external expansion.

Core Mezzanine Floor Benefits

-

Maximum Vertical Utilisation

Mezzanine installations add new floors without changing a building's footprint. This works in both small warehouses and large industrial spaces.

-

Cost Savings

A mezzanine eliminates high expenses tied to extending or relocating a site. That means a single investment leads to long years of use and a strong return on investment.

-

Adaptability for Growth

Modular structures grow with a business. Facilities often repurpose mezzanines for shifting warehouse, production, or administration needs.

-

Short Installation Timelines

An industrial equipment supplier can install most mezzanines with little impact on daily operations. This helps reduce downtime during upgrades.

-

Compliance and Safety

Properly engineered mezzanine floors support heavy loads securely. Structures meet strict safety requirements, supporting logistics, access, and storage activities reliably.

Where Mezzanine Floors Add Value

We work with facilities that need to separate production from storage, increase picking areas, or streamline materials handling. Mezzanines help organise workflow and clear paths for equipment like pallet jacks, lift tables, and waste management bins.

And for businesses that need tailored layouts, multi-tier mezzanines handle complex requirements smoothly, offering separate zones for storage, packing, and supervision.

Table: Facility Advantages After Installing Mezzanine Floors

|

Feature |

Pre-Mezzanine |

Post-Mezzanine |

|---|---|---|

|

Space Efficiency |

50–70% usage |

Up to 98% usage |

|

Expansion Costs |

High |

Significantly reduced |

|

Installation Time |

Weeks to months |

Days to a few weeks |

|

Flexibility |

Fixed structure |

Modular and scalable |

|

Storage Types |

Limited |

Racks, shelves, offices |

Relying on an experienced industrial equipment supplier helps facilities unlock every advantage of a custom mezzanine. The right solution supports operations today and grows alongside business needs tomorrow.

Key Factors to Consider Before Choosing a Mezzanine Floor

Selecting a mezzanine floor involves careful planning and review of your facility’s specific requirements. The right choice secures maximum return, smoother operations, and regulatory compliance.

Assessing Space and Load Requirements

Understanding the actual space and weight capacity needs is essential when selecting a mezzanine. First, we determine available vertical clearance, accounting for potential obstructions like lighting or sprinklers. Next, we review intended floor use like storage, offices, or production, since each requires different layouts and support strengths. If heavier goods or industrial equipment need storage, then we calculate uniform load capacity, usually expressed in kg/m², to prevent structural strain. Consulting the specifications provided by a qualified industrial equipment supplier helps confirm that load capacity aligns with our site’s requirements.

Mezzanine Load and Space Assessment Parameters

|

Parameter |

Storage Example |

Office Example |

Production Example

|

|---|---|---|---|

|

Minimum Height (m) |

4.5 |

4.2 |

4.8 |

|

Typical Load (kg/m²) |

350–750 |

250–400 |

500–1000 |

|

Layout Needs |

Open with racks |

Partitioned areas |

Machinery zones |

Evaluating Safety and Compliance Standards

Meeting local safety and compliance rules is critical for any mezzanine floor project. We ensure every installation adheres to SANS (South African National Standards) and OHS (Occupational Health and Safety) guidelines, including requirements for handrails, safe access points, and fire protection systems. If staff regularly work on or under the mezzanine, then additional features such as staircases with non-slip treads and safety gates become essential. A reputable industrial equipment supplier supports compliance with site assessments and product certifications.

Budget and Cost Implications

Budgeting accurately for a mezzanine floor means considering both upfront investment and long-term savings. We take into account the costs for materials, engineering, permits, and installation. While custom multi-tier mezzanines might require a higher initial outlay, they can unlock up to 50% space savings compared to expansion or relocation, according to industry estimates. If operating on a tighter budget, we evaluate standard rack-supported or shelf-supported mezzanines, which typically offer quicker returns on investment through faster installation and lower labour costs.

By reviewing these factors with your chosen supplier, balancing cost with quality, and tailoring features to long-term needs, we can set up a reliable, cost-effective, and safe mezzanine solution for any facility.

Types of Mezzanine Floors Available

Every facility faces unique challenges when it comes to storage, access, and materials handling. Whether you're expanding for more storage or increasing production space, picking the right Mezzanine Floor can drive both efficiency and savings. As an experienced industrial equipment supplier, we focus on solutions that match the specific needs of South African warehouses. Let’s look at the main types of mezzanines and see which one fits best for your space.

Structural Steel Mezzanines

Structural Steel Mezzanines form the backbone of many warehouse expansions. These platforms use free-standing steel columns and beams, making them suitable for heavy loads such as machinery, bulk storage, or assembly lines. They can span large areas without needing support from existing racks or shelves. Their robust construction allows for easy reconfiguration or relocation as operational demands change. For facilities with open floor plans or those needing adaptable workspace, structural steel offers lasting durability and maximum flexibility.

Rack Supported Mezzanines

Rack-supported mezzanines take advantage of your current racking systems for structural support. This type integrates directly with pallet racking, using uprights to bear the load of the added floor above. Businesses already using selective or drive-in racks often add these mezzanines to maximise vertical storage. They provide new picking areas, overflow space, or walkways—all without expanding your building’s footprint. It’s a cost-effective option for streamlining order fulfilment or separating product lines.

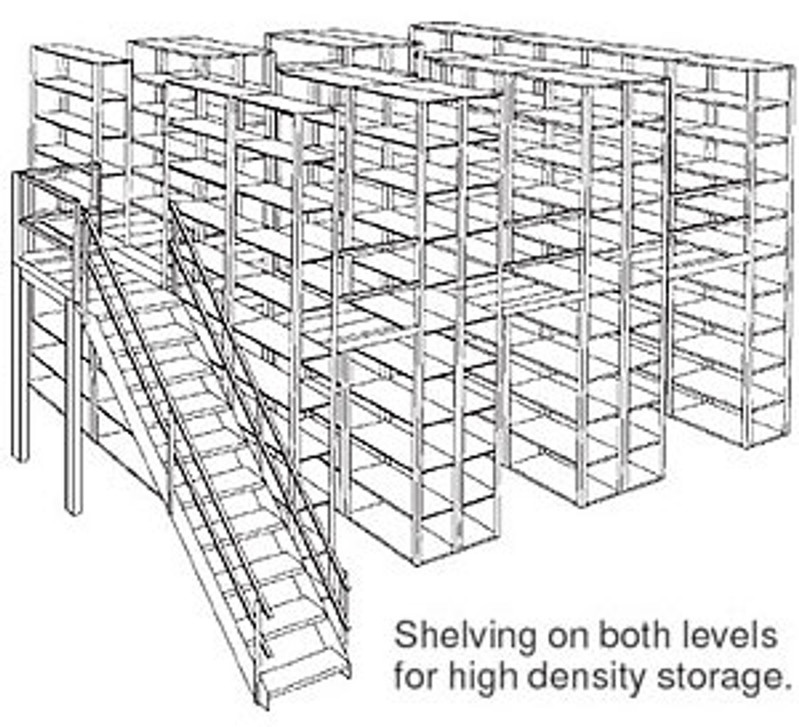

Shelf Supported Mezzanines

Shelf-supported mezzanines sit on top of robust shelving units, unlocking extra floorspace for picking, sorting, or light assembly. Facilities handling smaller items or parts often benefit most from this type. By stacking usable space above existing shelving, these mezzanines efficiently manage inventory without overcrowding the ground level. Consider shelf-supported designs if your operation relies on high-density storage for small components, tools, or finished goods.

We view every mezzanine installation as a tailored solution, matching business needs with the reliable design, supply, and installation expertise of a trusted industrial equipment supplier. If you’re unsure which mezzanine type fits your goals, we assess your current layout and material flows to recommend a system optimised for your workflow.

Installation and Customisation Options

Choosing the right Mezzanine Floor means weighing both installation methods and the full range of customisation options. Each facility has unique requirements, so our approach adapts to specific operational demands and site conditions.

Design Flexibility

Design flexibility in a Mezzanine Floors lets us tailor installations to your space and workflow. We create rack-supported mezzanines that integrate with existing storage racks, perfect for maximising every vertical metre in high-bay warehouses. For growing operations, shelf-supported mezzanines leverage heavy-duty shelving, offering another level of high-volume storage without major building work. Multi-tier designs are possible for sites with high ceilings, making two or even three extra floor levels practical for offices, picking, or extra storage.

Why limit layouts? We work around obstructions like columns or HVAC units, custom-configuring access points and stairs for better traffic flow. Need integrated office pods, handrails, conveyors, or fire-rated staircases? All these fit into the plan, making sure each Mezzanine matches business operations and safety needs.

Flooring and Finishing Choices

Flooring and finishing choices in a Mezzanine system affect durability, safety, and maintenance. We offer high-load structural steel decks for rugged manufacturing uses, plus timber or composite alternatives for lighter-duty needs such as offices or inventory zones. Anti-slip coatings help prevent workplace accidents, especially in high-traffic or materials handling areas.

Looking to streamline cleaning or meet hygiene standards? Sealed or epoxy-coated decks work well in environments like food storage or healthcare parts warehousing. Plus, we supply modular guardrails, kickplates, and mesh infill panels to meet all warehouse safety requirements.

And let's not overlook how a trusted Industrial Equipment Supplier helps facilities integrate Mezzanine floors with existing materials handling equipment. We factor in pallet gates for safe loading, custom lifts, or conveyor connections, ensuring the entire installation works as a seamless storage and workflow unit. Looking for something particular? Our process ensures every solution aligns with the warehouse’s changing needs, keeping things flexible and efficient.

Maintenance and Longevity Considerations

Maintaining a mezzanine floor plays a key role in protecting our investment and keeping operations safe. When we choose a suitable mezzanine, we secure an extended service life and help minimise ongoing costs. Every business wants reliability from industrial equipment; mezzanine longevity often hinges on a few important factors.

Key Maintenance Tasks

- Scheduled Inspections

Regular inspections spot structural wear, corrosion, or signs of overloading. Spotting issues early helps us avoid large repair bills and keeps staff safe.

- Cleaning and Housekeeping

Keeping the mezzanine clear, particularly around load-bearing supports and walkways, reduces trip hazards and preserves protective coatings.

- Component Checks

Checking handrails, kickboards, stairs, bolts, and flooring panels keeps the structure strong and prevents accidents. A trusted industrial equipment supplier can provide guidance on what to check monthly or annually.

- Load Controls

Monitoring distributed loads prevents accidental overloading. For example, if the floor is rated for 500kg/m², spreading out heavy goods such as pallets or drums lessens stress on the frame.

Factors That Extend Mezzanine Lifespan

- Material Choice

Steel constructions resist rust and daily wear better than timber. Coating systems like powder-coating or galvanising further increase resistance to moisture or industrial chemicals.

- Professional Installation

Getting installation from an experienced industrial equipment supplier ensures compliance with safety codes and best practices, preventing unequal weight distribution or fastener loosening.

- Adaptability for Upgrades

Modular mezzanine designs make future upgrades simple. Swapping panels, rails, or even integrating wheelie bins, racks, or trolleys keeps the system agile as needs change.

Durability Statistics Table

|

Mezzanine Floor Factor |

Typical Lifespan (Years) |

Notes |

|---|---|---|

|

Steel Structure |

20–30 |

With regular maintenance |

|

Timber Decking |

10–15 |

Lower with high moisture exposure |

|

Galvanised Coatings |

25–35 |

Ideal for humid or chemical environments |

|

Powder-Coated Surfaces |

15–25 |

Requires surface cleaning, not abrasive |

Role of the Industrial Equipment Supplier

Working closely with an industrial equipment supplier with experience in mezzanine solutions streamlines maintenance scheduling and quality assurance. They offer:

- Maintenance plans calibrated to facility use

- Spare parts and upgrades matched to the existing floor

- Advice on compliance with South African standards

Maintaining a mezzanine floor doesn't just enhance safety, it drives down total cost of ownership and keeps storage and material handling efficient for years.

Conclusion

Choosing the perfect mezzanine floor opens up new possibilities for any facility looking to maximise space and efficiency. By working with trusted experts and carefully considering your unique requirements, we can unlock valuable storage and operational benefits while keeping costs under control.

Let’s ensure our facility is ready for growth and change by investing in a mezzanine solution that’s built to last and tailored to our needs. With the right approach, we’ll enjoy a safer, more productive space that supports our business for years to come.

Frequently Asked Questions

What are the main benefits of installing a mezzanine floor in a warehouse?

Mezzanine floors increase storage capacity by utilising unused vertical space, allowing for additional storage, office, or production areas. This solution is cost-effective, often saving 30%–50% compared to building extensions or relocating. Mezzanines are adaptable, quick to install, and help facilitate better workflow while keeping the facility compliant with safety regulations.

How do I determine if my warehouse is suitable for a mezzanine floor?

You should assess your available vertical clearance, the structure’s load-bearing capacity, and the intended use of the mezzanine. Consulting with a qualified supplier can help evaluate your current workflow, space needs, and safety requirements to determine suitability and select the right mezzanine type.

What types of mezzanine floors are available?

Common types include Structural Steel Mezzanines for heavy loads, Rack Supported Mezzanines that make use of existing racking systems for cost-effective vertical storage, and Shelf Supported Mezzanines for high-density storage of smaller items. Your choice depends on your facility’s specific operational needs.

Are mezzanine floors safe and compliant with regulations?

Yes, when designed and installed by experienced professionals, mezzanine floors comply with local safety standards such as SANS and OHS guidelines. Features like handrails, anti-slip coatings, and regular inspections help keep them safe. Always verify that your installation meets regulatory and safety requirements.

Can mezzanine floors be customised for my facility’s needs?

Absolutely. Mezzanine floors offer a high level of design flexibility. They can be customised to fit existing layouts, accommodate obstructions, and support specific operational activities. Options include tailored flooring, various finishes, and integration with existing material handling equipment for seamless workflow.

How long does it take to install a mezzanine floor?

Installation timelines depend on the mezzanine’s size and complexity, but most can be completed within a few days to several weeks. Using experienced suppliers ensures swift and compliant installation, minimising disruption to warehouse operations.

How do mezzanine floors impact long-term costs?

While mezzanines require an upfront investment, they typically result in significant long-term savings by avoiding relocation costs and providing space efficiencies. Regular maintenance further extends their lifespan, reducing replacement and repair expenses over time.

What maintenance is required for mezzanine floors?

Routine maintenance includes regular inspections, cleaning, and timely repairs of structural components, flooring, and safety features. This helps prevent issues, ensures ongoing safety compliance, and maximises the mezzanine’s service life.

Can mezzanine floors be expanded or reconfigured in the future?

Yes, one of the key advantages of mezzanine floors is their adaptability. They can often be expanded, reconfigured, or relocated as your business needs evolve, making them a flexible long-term solution for growing operations.

Why should I work with a professional mezzanine supplier?

A professional supplier, such as Dreymar Industrial, offers tailored solutions that address your facility’s unique needs. They ensure optimal design, regulatory compliance, quality installation, and ongoing support, helping you maximise space, operational efficiency, and return on investment.