Why the Choice Matters

The right racking system shapes how your business operates, from safety and speed to space efficiency. At Dreymar Industrial, we help South African businesses choose between heavy-duty industrial racking and lighter retail-focused shop racking based on real loads, workflows, and growth plans.

Our solutions cover the full spectrum: pallet racking, drive-in racking, and cantilever systems for warehouses, alongside gondola and mobile shelving for shops and backrooms. We design layouts that maximise floor space, improve product flow, and keep facilities compliant with SANS standards.

Key Takeaways

- Industrial racking is designed for heavy pallets and long loads (pallet racking, drive-in, cantilever), while shop racking is for lighter retail stock (gondola shelving, PVC, and stainless options).

- Your decision should consider load capacity, aisle access, and stock rotation: forklifts and pallet moves for warehouses; hand picks, resets, and displays for retail.

- To delay costly expansions, integrate mezzanines, mobile shelving, and modular bays that boost density and speed.

- Safety and compliance are non-negotiable: load ratings, engineered anchors, signage, and regular inspections protect staff and assets.

- Always weigh total cost of ownership and lead times — including materials, accessories, and lifecycle support from a qualified racking supplier.

- For faster installs and compliance-ready systems, searching “Racking near me” connects you with local expertise and stock availability.

When Industrial Racking Fits

Industrial racking is built for strength and scale:

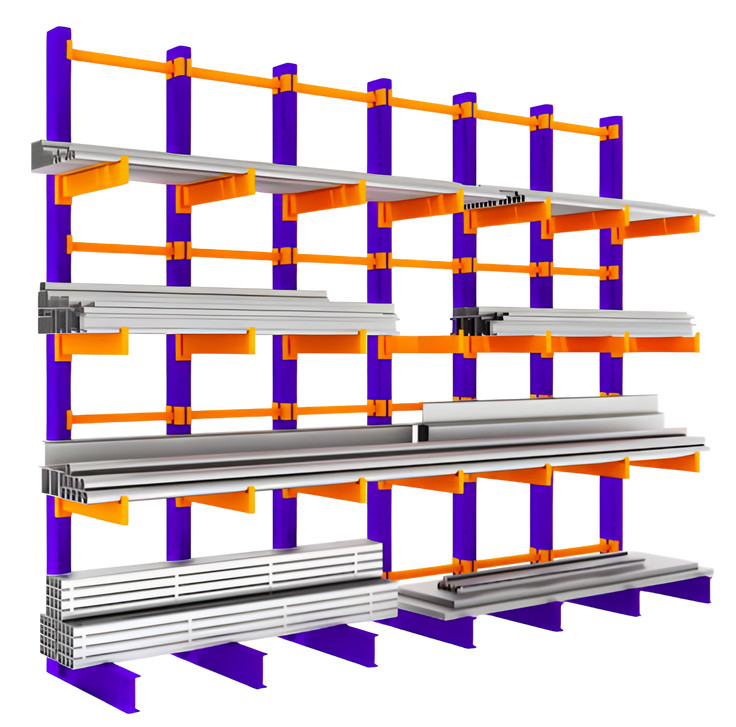

- Pallet racking, drive-in racking, and cantilever racking for bulk storage and long goods.

- High-bay layouts to maximise cube space, with forklift and pallet jack access.

- Drive-in lanes for bulk SKUs with low variety (ideal for last-in-first-out rotation).

- Cantilever arms for timber, pipe, and oversized loads.

- Mobile shelving and cabinets for spares and tooling near production lines.

- Safety-certified towers and mezzanines when vertical expansion is needed.

When Shop Racking Fits

Shop racking prioritises visibility, flexibility, and accessibility:

- Gondola shelving for front-of-house displays and frequent planogram changes.

- PVC shelving for hygienic retail or food-prep areas.

- Stainless steel shelving for wet zones or high-clean environments.

- Mobile shelving in storerooms where backroom space is tight.

- Office and filing cabinets for admin and staff areas.

Key Differences at a Glance

|

Factor |

Industrial Racking |

Shop Racking |

|

Loads |

Pallets, bulk SKUs, long goods |

Lighter cartons, retail stock |

|

Access |

Forklifts, pallet jacks, batch moves |

Hand picks, frequent resets |

|

Aisles |

Designed for MHE turning radius |

Designed for browsing & staff safety |

|

Rotation |

FIFO/LIFO pallet strategies |

Planograms & fast replenishment |

|

Flexibility |

Reconfigure beams & bays |

Reconfigure shelves & accessories |

Cost and Implementation Considerations

Upfront Investment vs Lifecycle Costs

- Industrial racking requires higher upfront investment for heavy-duty steel, engineered load ratings, and safety features.

- Shop racking costs less initially but may need more frequent resets and accessories.

Key Cost Drivers

- Material thickness and finishes (powder coat, galvanised, stainless).

- Engineering (load deflection, anchor design, certification).

- Accessories (mesh decks, barriers, lockers).

- Flexibility (modular vs fixed).

Tip: Always compare total cost of ownership — not just the per-unit price. Space savings and compliance can reduce long-term spend.

Integration with Materials Handling Equipment

- Warehousing: Pair pallet racking with forklifts, dollies, and conveyors.

- Retail: Match gondola shelving with trolleys and small pick carts for easy restocks.

- Multi-level sites: Integrate mezzanines and access towers to increase density without moving premises.

Avoiding Common Mistakes

- Mixing heavy pallets on light-duty shelves.

- Designing aisles too narrow for forklifts.

- Choosing deep-lane racking for short-life SKUs where FIFO matters.

- Locking into fixed shop fittings when frequent resets are required.

Quick Fit Guide

- Choose Industrial Racking → pallets, long goods, and bulk SKUs in warehouses.

- Choose Shop Racking → cartons, small SKUs, and retail displays.

- Hybrid layouts work best for businesses with both retail and warehouse operations.

Conclusion

The right racking system isn’t just about storing stock, it’s about improving flow, protecting people, and making your space work harder. At Dreymar Industrial, we don’t just sell racking; we engineer solutions that fit your loads, your layout, and your long-term growth.

If you’re unsure where to start, let’s run a site audit and design session. We’ll map your top movers, validate load data, and present layouts that balance cost, compliance, and performance. Whether you need industrial racking, shop shelving, or a hybrid setup, Dreymar Industrial has the experience, stock, and support to make it work.

Frequently Asked Questions

What’s the difference between industrial racking and shop racking?

Industrial racking is built for heavy-duty pallets, long loads, and high bay storage. Shop racking is designed for retail stock, visibility, and customer access.

How do I know which racking my business needs?

Start with load type, handling method (forklift vs hand-pick), aisle widths, and compliance needs. Warehouses need industrial systems; retail requires shop racking.

What safety standards apply in South Africa?

All racking should meet SANS codes, carry engineered load signage, and be inspected regularly. Anchoring, bracing, and load ratings must be certified.

Can I combine both types?

Yes. Many businesses run industrial racking in warehouses and shop shelving in front-of-house or backrooms. Hybrid designs optimise both storage and display.

How often should racking be inspected?

Do weekly checks in-house, and schedule annual inspections by a qualified racking supplier. Always inspect after impacts or layout changes.